Tag: TPM

Early Equipment Management – Total Productive Maintenance

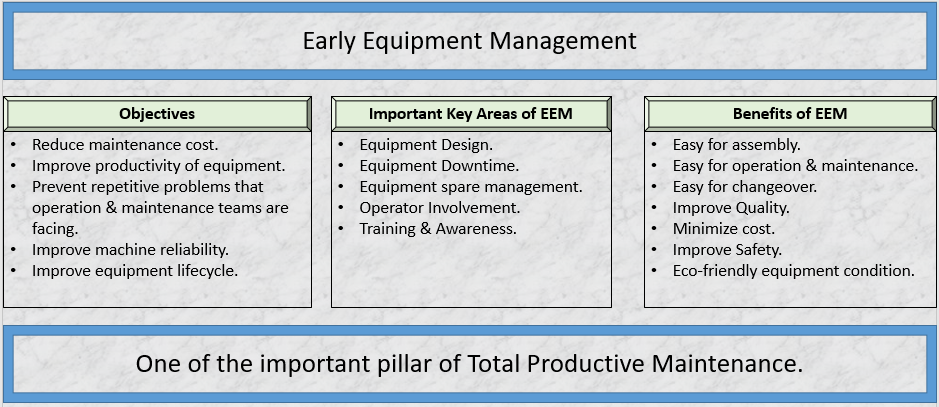

Early equipment management is a one of the total productive maintenance pillars. EEM pillar is very helpful to improve & maintain lifecycle of equipment. To improve equipment reliability, productivity, defects, safety & quality EEM pillars play a vital role. EEM pillar closely work with the operations, finance and maintenance team & focused to improve productivity of equipment. The important key areas that EEM pillar mainly works on too easy for assembly, operations, changeover, quality, cost, safety and eco-friendly.

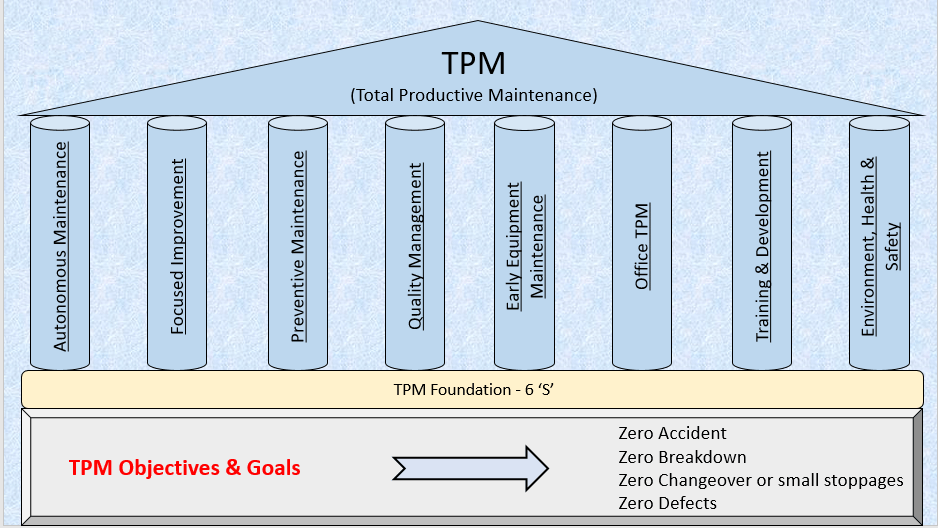

What is the eight pillar of total productive maintenance?

Total Productive Maintenance is a concept of lean manufacturing and majority applicable to all sectors. TPM concept is majority useful for increasing asset reliability towards desired performance. One of the goals of an organization is to utilize assets (equipment, machines) effectively. To utilize the entire asset and its caring is very important just like a mother care for her child & continuously makes efforts to make it strong in all direction. A similar concept will apply to equipment & machines. So in short, to cut the story long TPM is all about maintaining assets in such a way to utilize asset effectively.