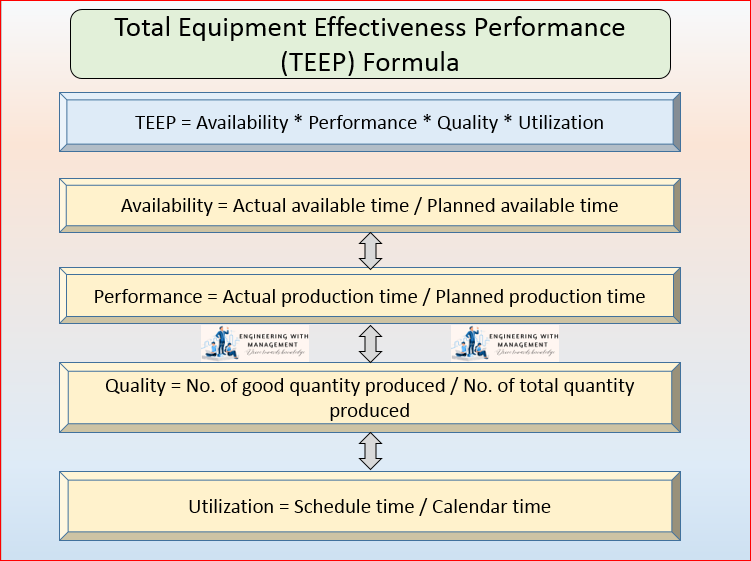

What is Total Equipment Effectiveness Performance (TEEP) , TEEP Formula and Calculation , Difference between OEE and TEEP

Total Equipment Effectiveness Performance (TEEP) is an extended version of overall equipment effectiveness (OEE) to measure machine or equipment overall output in terms of time basis. Each and every organization planning to procure new equipment or asset must backside plan to utilize assets in the best possible way and focus on minimizing the cycle of…