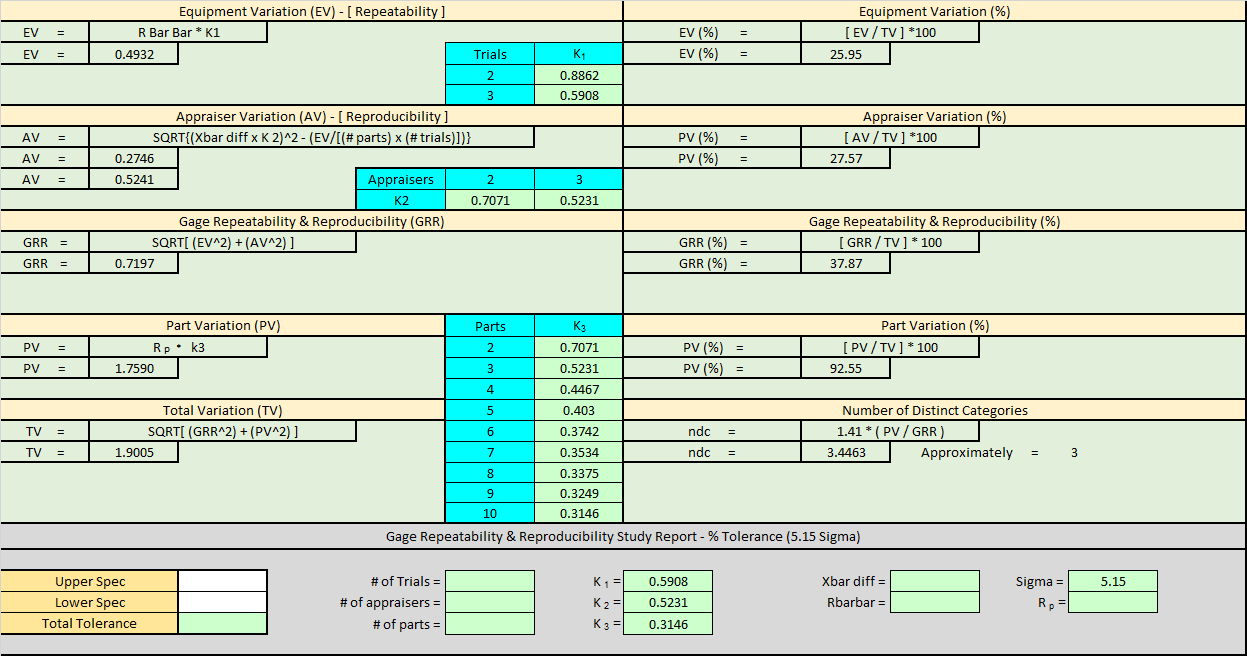

Gage Repeatability & Reproducibility Study

Gage R & R study is part of measurement system analysis. (MSA – six-sigma concept), The meaning of gage r & r is gage Repeatability & Reproducibility. During the gauge r & r study, one thing you need to keep in mind is that the gauge r & r study does not give an idea…