MOST – Maynard Operation Sequence Technique

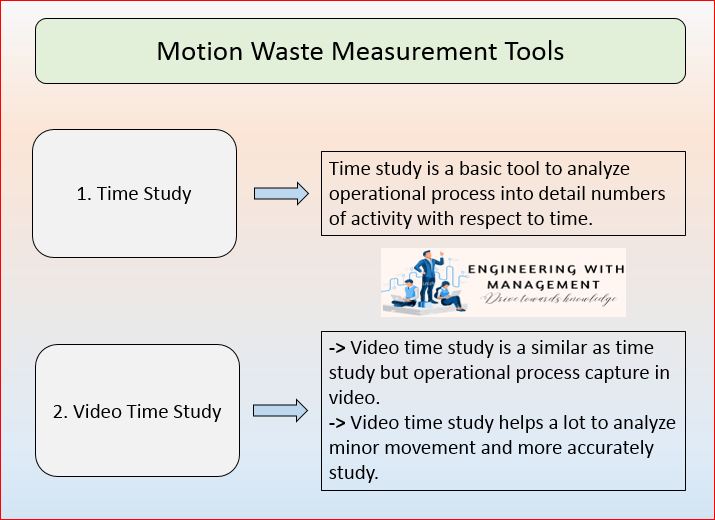

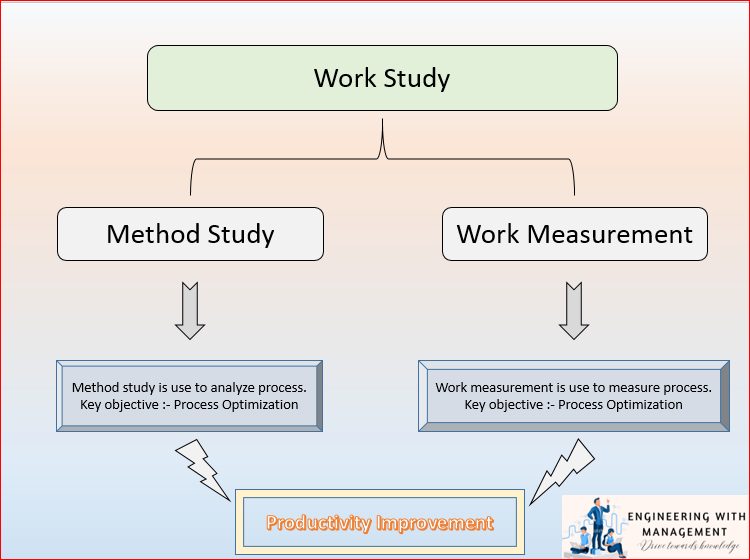

Maynard’s operation sequence technique is a very important tool of work-study and is widely used to develop manpower standards based on studies. Time study is a manual process to observe and measure processes but MOST is a very advanced technique to conduct the study of different processes in a very precise way. Now day MOST…