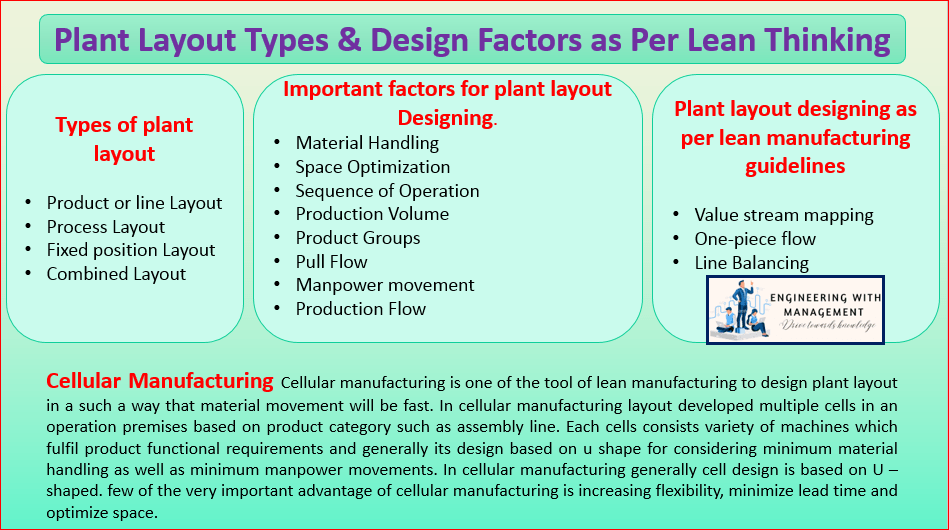

Plant Layout Types and Design Factor as Per Lean Thinking

Plant layout is a basically design of premises in a such a way to perform manufacturing activity and produces products and services. Plant layout is changes as per the manufacturing sequence of product and also its varies industry to industries. Now a day’s many industries applied concept of industrial engineering as well as lean manufacturing…

Read More “Plant Layout Types and Design Factor as Per Lean Thinking” »