Author: engineeringwithmanagement@gmail.com

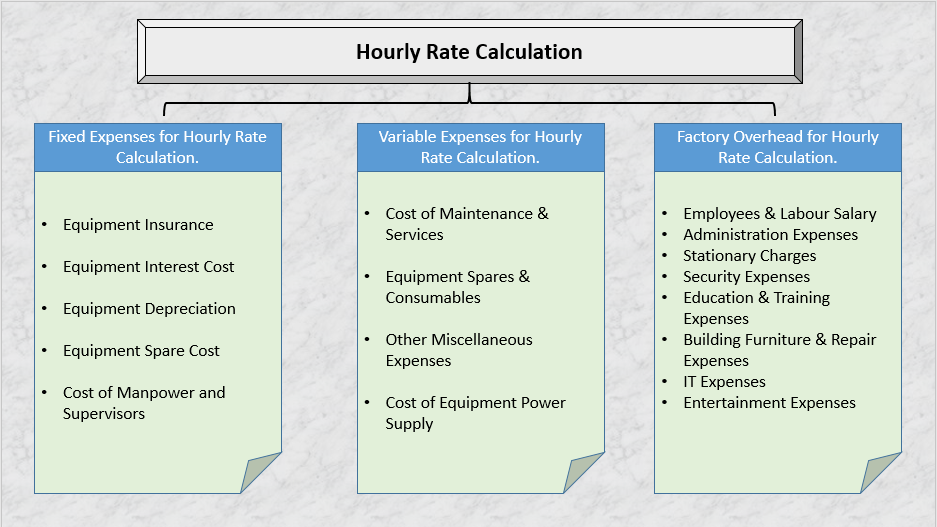

Machine Shop Hourly Rate Calculations

Now a day’s hourly rate term is very popular in project based and other industries. It is also very helpful for analyze machine & manpower performance on financial basis. There are several parameters required for calculating man and machine hourly rate, in this article we will discuss each parameter in detail. Basically in project based…

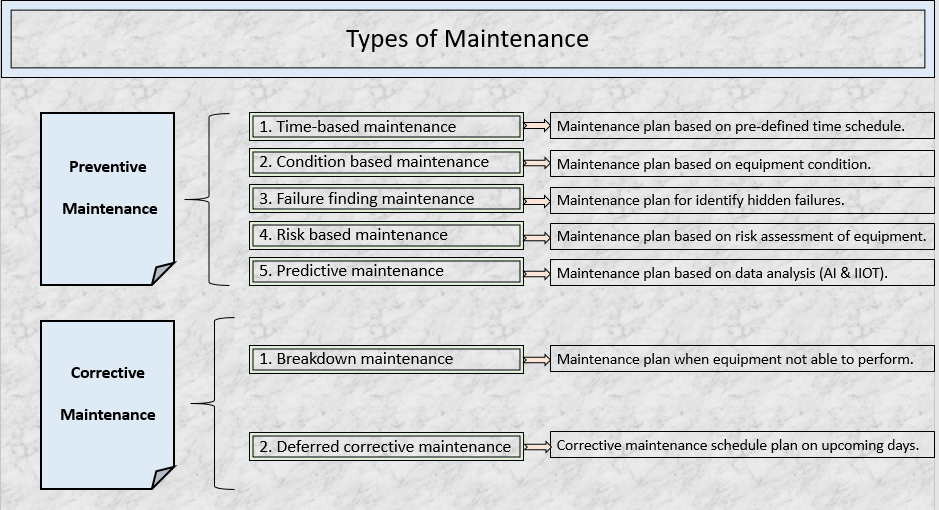

What are the Types of Preventive & Corrective Maintenance

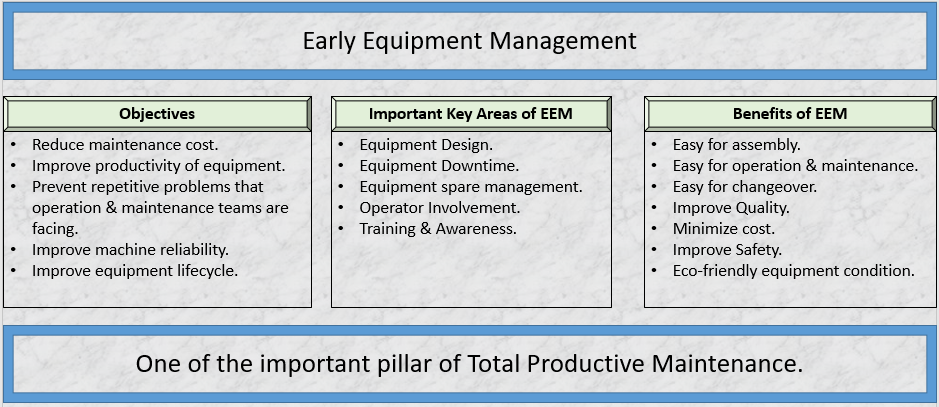

Early Equipment Management – Total Productive Maintenance

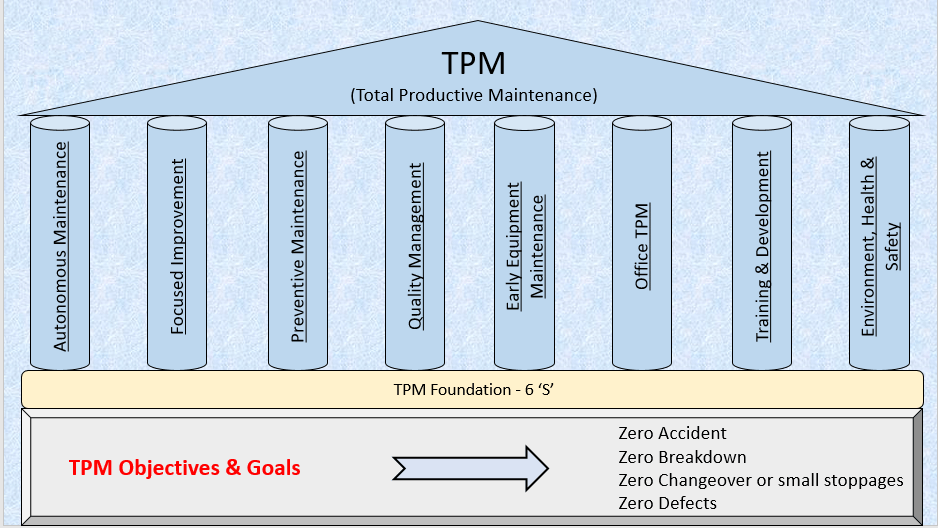

Early equipment management is a one of the total productive maintenance pillars. EEM pillar is very helpful to improve & maintain lifecycle of equipment. To improve equipment reliability, productivity, defects, safety & quality EEM pillars play a vital role. EEM pillar closely work with the operations, finance and maintenance team & focused to improve productivity of equipment. The important key areas that EEM pillar mainly works on too easy for assembly, operations, changeover, quality, cost, safety and eco-friendly.

What is the eight pillar of total productive maintenance?

Total Productive Maintenance is a concept of lean manufacturing and majority applicable to all sectors. TPM concept is majority useful for increasing asset reliability towards desired performance. One of the goals of an organization is to utilize assets (equipment, machines) effectively. To utilize the entire asset and its caring is very important just like a mother care for her child & continuously makes efforts to make it strong in all direction. A similar concept will apply to equipment & machines. So in short, to cut the story long TPM is all about maintaining assets in such a way to utilize asset effectively.

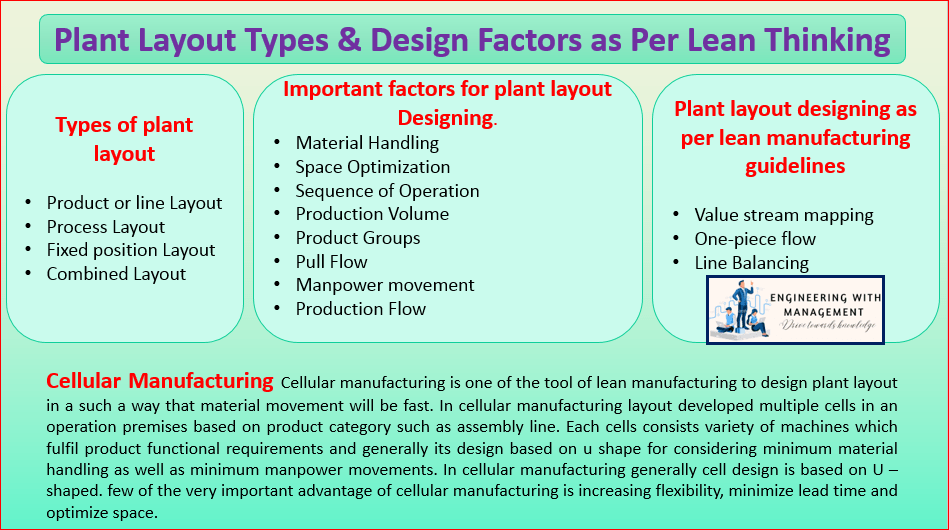

Plant Layout Types and Design Factor as Per Lean Thinking

Plant layout is a basically design of premises in a such a way to perform manufacturing activity and produces products and services. Plant layout is changes as per the manufacturing sequence of product and also its varies industry to industries. Now a day’s many industries applied concept of industrial engineering as well as lean manufacturing…

Read More “Plant Layout Types and Design Factor as Per Lean Thinking” »

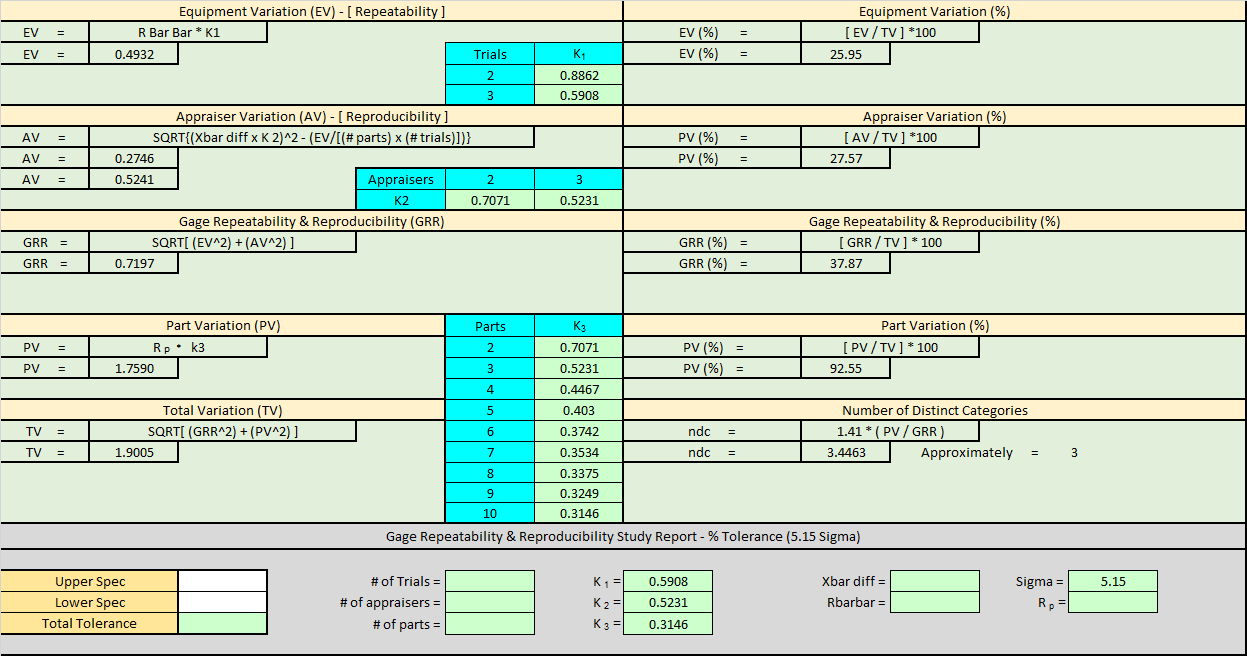

Gage Repeatability & Reproducibility Study

Gage R & R study is part of measurement system analysis. (MSA – six-sigma concept), The meaning of gage r & r is gage Repeatability & Reproducibility. During the gauge r & r study, one thing you need to keep in mind is that the gauge r & r study does not give an idea…

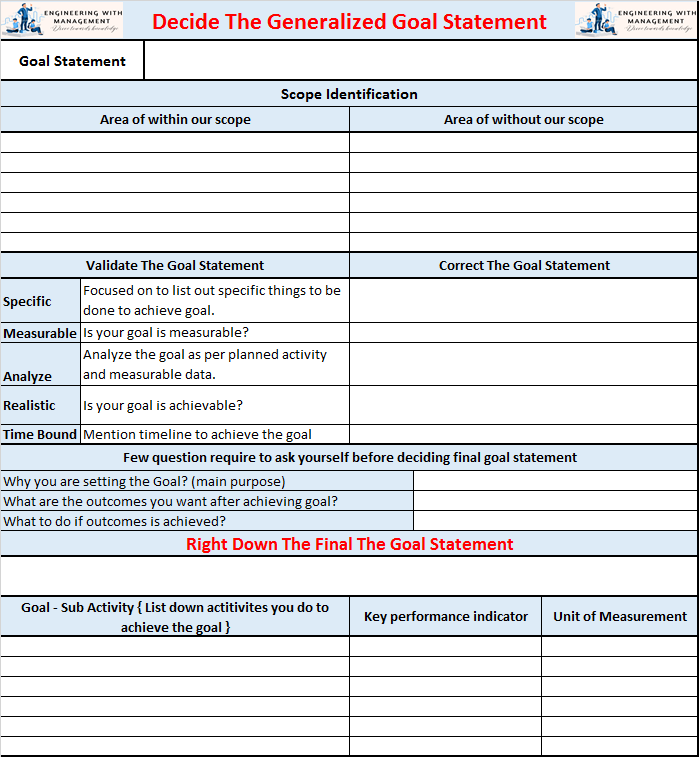

Importance of Goal Setting in Life

The main purpose of live life for everyone is fulfil dreams and achieve what people want. So, for fulfilling people dreams and wants, there is a structural management process for goal setting that very much helpful to achieve the desired outcomes either it is personal or professional. First of all, we are able to understand…

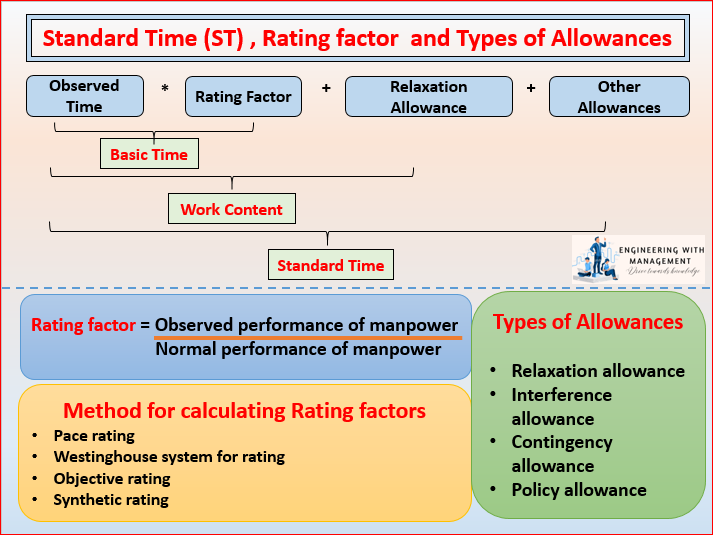

Standard Time , Rating factor and Types of Allowances

Now a day every organization is focused to improve operational processes based on measuring different parameters. As per lean manufacturing guidelines, one of the very best ways to monitor and measure equipment, product, or process output is based on a time basis rather than an output basis. output is considered a by-product if we minimize…

Read More “Standard Time , Rating factor and Types of Allowances” »

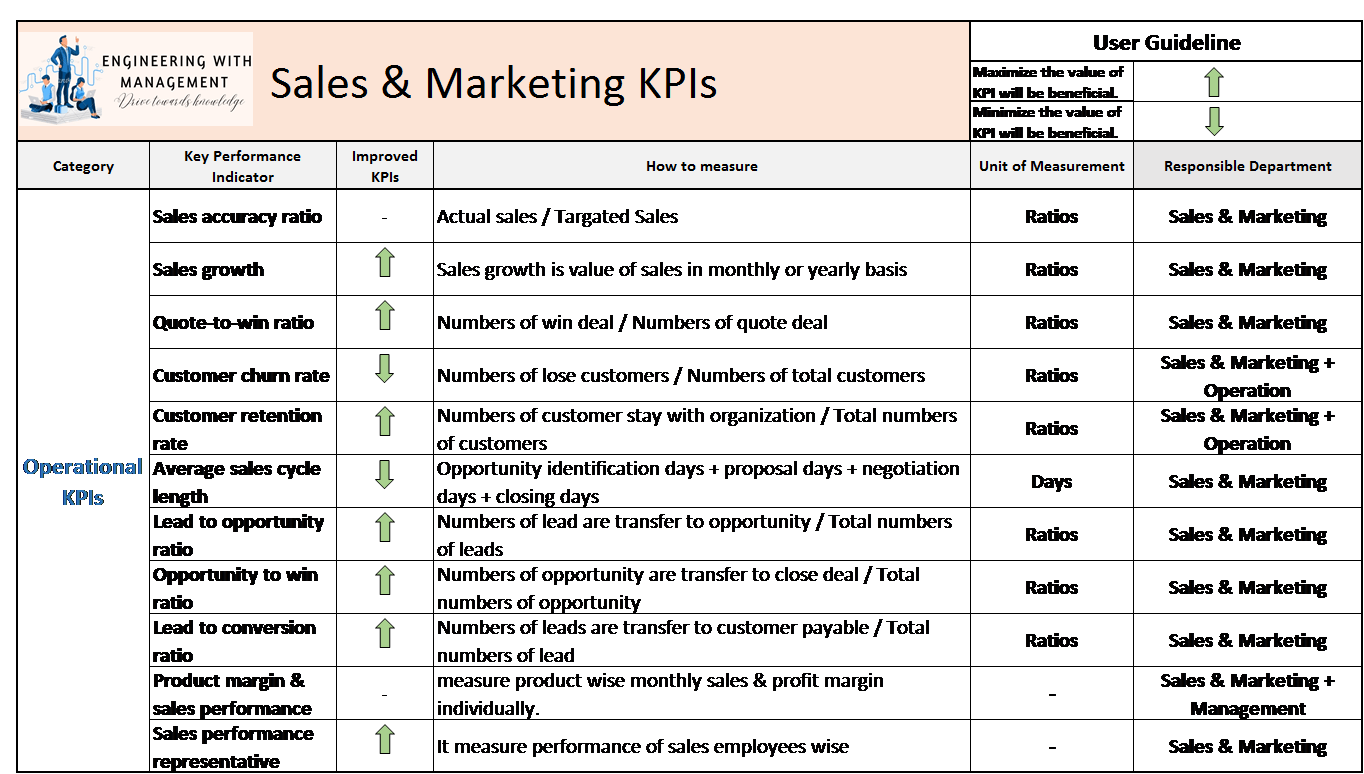

Sales & Marketing KPIs

Sales KPI is a one of the important key performance indicators to improve business performance. To monitor each activity individually in an effective way perfect KPI identification is very essential. Sales KPIs is help to monitor and improve performance of each activity. In general way business growth is directly proportional to product sales growth. Now…